President Xi Jinping has emphasized the importance of taking into account the battlefield, the troops and the future in order to build world-class military medical universities, as the nation elevates the people's armed forces to worldclass standards.

Pandas headed for Madrid in sign of bilateral friendship

Pandas headed for Madrid in sign of bilateral friendship

Climate change blamed for heavy rain in the south

Climate change blamed for heavy rain in the south

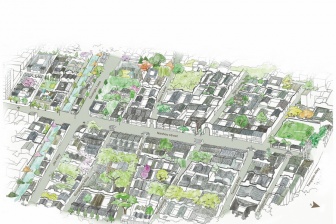

Bringing the history back to the homes

Bringing the history back to the homes

Industry forum sheds light on AI's role in filmmaking

Industry forum sheds light on AI's role in filmmaking

Chongren ancient town preserves rich heritage

Chongren ancient town preserves rich heritage

京公网安备 11010502032503号

京公网安备 11010502032503号